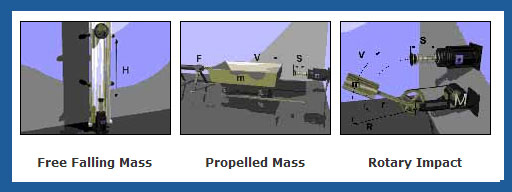

Based upon the above illustrations we calcualte the energy to be absorbed of the impact system . This energy capacity and impact speed is compared with the existing models and suitable model is selected. In case the impact data is already known please inform us the energy requirement so that we can size and quote the model for you.

Based upon the above illustrations we calcualte the energy to be absorbed of the impact system . This energy capacity and impact speed is compared with the existing models and suitable model is selected. In case the impact data is already known please inform us the energy requirement so that we can size and quote the model for you.

All manufacturing processes involve movement of some kind. In machine tools this can involve linear transfers, rotary index motions, fast feeds etc. At some point these come to a stop or change directions.

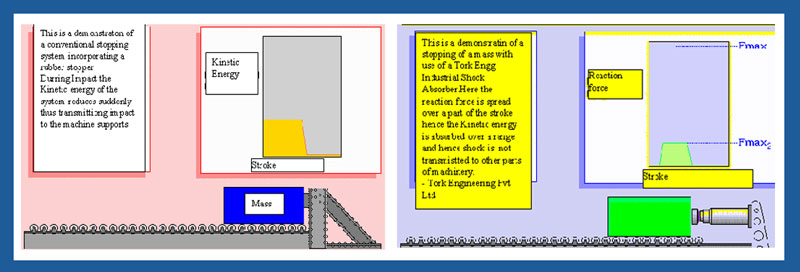

Every object posses kinetic energy or as a result of its motion, and if the object changes direction or is brought to rest, the dissipation of this kinetic energy can result in destructive and unbalanced impact forces within the structural and operating members of the machine or system.

There is a need to increase productivity of machinery .Thus tending to increase the transit speeds. This also means rapid reversal of the reciprocating mass.This may result into a impact which might damage the machinery components or change settings , creat unpleasent noises and finally result into loss of productivity.

An increase in production rates is only possible by dissipating this kinetic energy smoothly and thereby eliminating destructive deceleration forces.

One method is mechanical represented by springs or resilient bumpers, such as rubber stops. Using this method, the kinetic energy is stored in the spring during deceleration resulting in potential energy stored in the spring being transferred back to the object at the end of stroke.